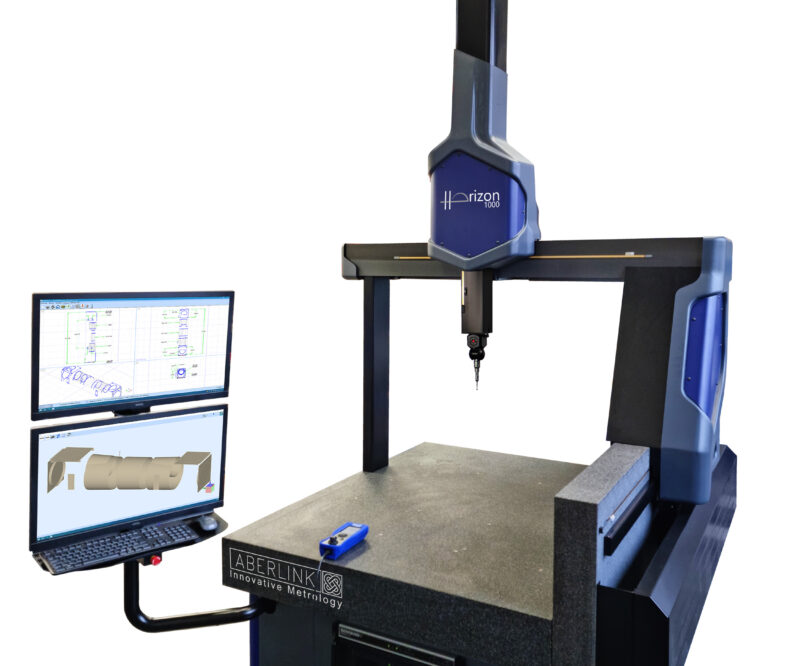

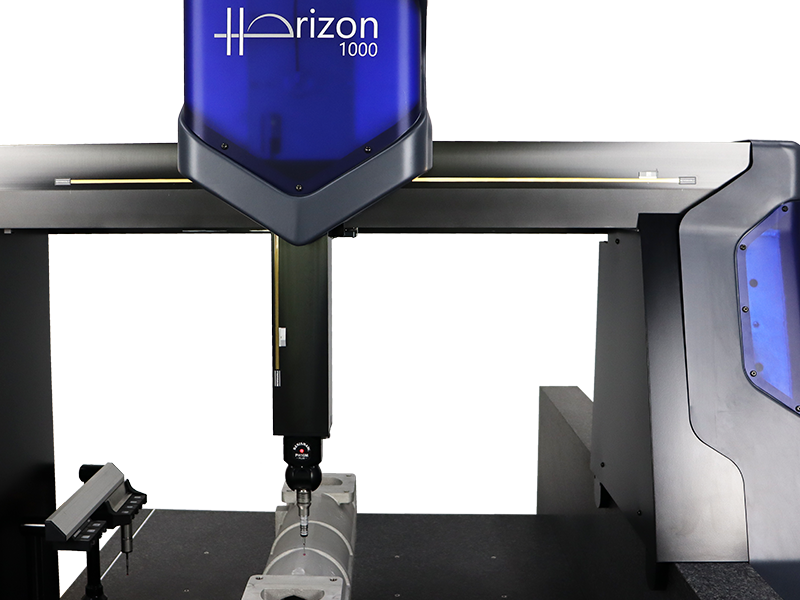

Building on the enormous success of the Horizon 800, the Horizon 1000 uses the same frictionless linear motors but boasts a greater X-Y-Z axis movement. The complete architecture of the Horizon 1000 has been refined to maximize the utilization of components now employed in the Horizon 800, all the while enhancing the stiffness-to-weight ratio throughout the bridge assembly. Above all, The stiffness-to-weight ratio has been improved by the carriage assembly’s size and weight reduction without sacrificing metrology performance; the Z-axis motor’s power has been increased to maximise its performance; and the left-side air bearing assembly’s unique extruded profile keeps weight to a minimum while maintaining stiffness. The Y-axis rail is 200mm taller to allow for the same right-side linear drive system to be common and improve rigidity.

With its rapid silent, and smooth motion, the Horizon 1000 is a remarkable coordinate measuring device that is perfect for contact scanning. Additionally, it has a standard for first-term accuracy of less than two microns. Because they don’t have any worn parts and are non-contact, linear motors are the ideal option for CMM drives because they increase reliability and require less maintenance.

|

Horizon 1000 CMM |

Maximum Performance |

SPECIFICATION

| Axis Travel (mm) | X 1000 Y 1200, 2000 Z 800 |

| Overall Size (mm) | X 1603 Y 1830, 2630 Z 3110, 3160 |

| Motion | CNC |

| Structure | Bridge |

| Suitable for | Inspection Room |

| Drive Type | Linear |

| *Volumetric Accuracy | TP20 (1.9 + L/250)µm TP200 (1.8 + L/250)µm SP25M (1.75 + L/250)µm |

| Scale Resolution | 0.1µm |

| **Optimum Temp Range | 18 – 22°C |

| Operational Temp Range | 5 – 45°C |

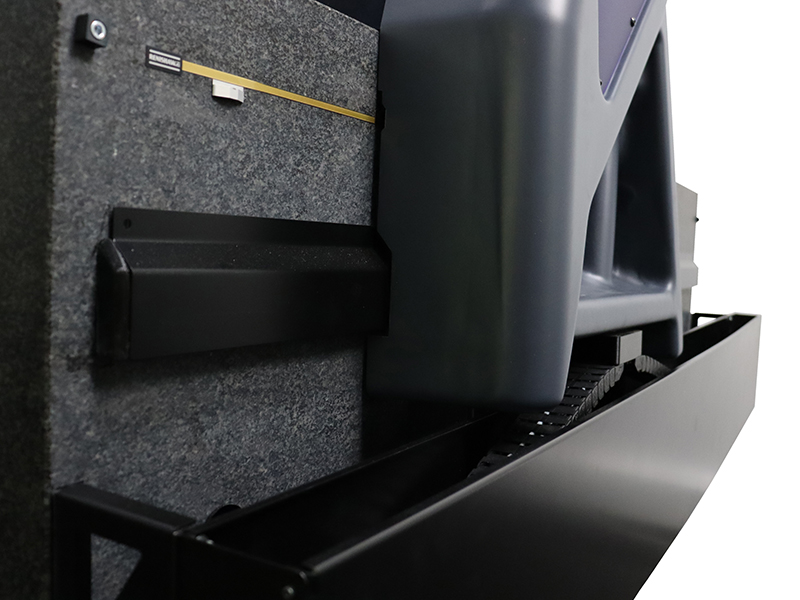

| Table Construction | Solid Granite |

| Table Load Capacity | 1000kg |

| Max. Velocity Vector | 1000mm/sec |

| Max. Acceleration Vector | 1000mm/sec² |

| Air Required | Yes |

| Air Consumption | 65 l/min (1.8 cfm) |

| Required Air Pressure | 5 bar (72 psi) |

| Aberlink Camera Support | Yes |

*Maximum Permissible Error MPEE within the thermal limits defined for optimum temperature range. **Installation environmental thermal limits: Rate of change <1°C/hr and <2°C/24hr. Temperature gradient <1°C/m

- *Minimum measuring range specified because the usable volume isn’t cubic.**Maximum Permissible Error MPEE, according to an adapted ISO10360-2 2009 test to suit the Fulcrum, within the thermal limits defined for optimal temperature range.***The machine should not be positioned where it will be subjected to rapid changes in temperature. Max rate of ambient temperature change should not be more than 1°C/hour.