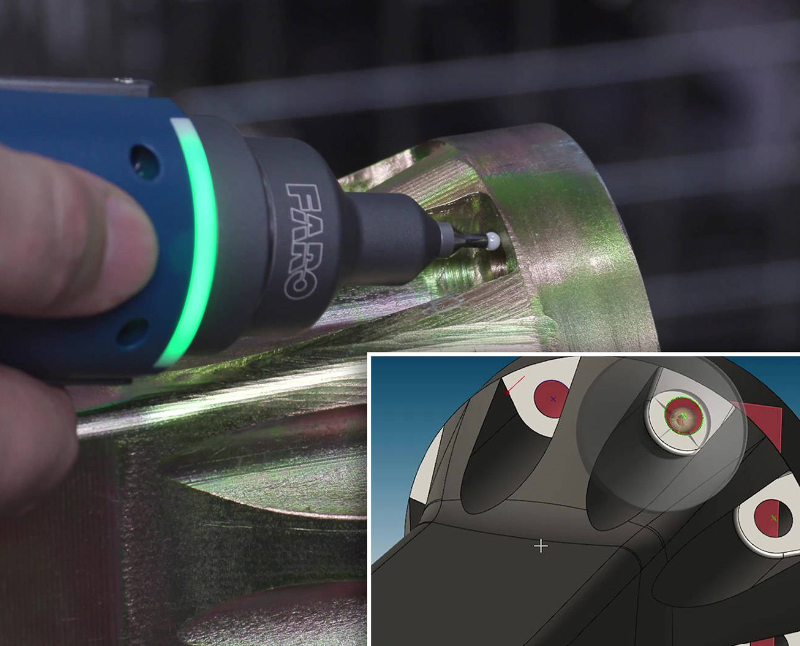

With conventional hand tools, examinations take a long time and clutter up the shop floor. With just one effective, stylish, tough coordinate measurement machine (CMM), the Gauge Max FaroArm revolutionizes the process and enables machine shops and small production lines to fulfil even the most exacting quality criteria. The Gauge Max FaroArm portable CMM configures in a matter of seconds and provides accurate measurements for speedy comparison to nominal CAD data.

| Gage Max FaroArm | Maximum Performance |

Applications for Architecture, Engineering, and Construction

During first-article, in-process, and inbound part inspections, confirm dimensional accuracy and spot deviations from normative CAD data.

- As-built Modelling and Capture that is Quick.

- Preserving historical sites.

- Asset and facility management with a digital twin.

Pre-incident preparation and forensic analysis

Engineering and Product Design that is quicker and more accurate

Rapid prototyping should be accelerated for quicker market entry. Record every aspect of the environment so that it can be used to create safety systems, investigate crime or accident sites, recreate bullet trails, or determine the origin of a fire.

ScanArm Features

Wherever needed, operators can do precise 3D examination.

Every operator consistently receives the same outcomes.

Rework, scrap, and inspection bottlenecks are decreased by precision measurement.

Providing competitive service entails extending the product’s lifespan while lowering the overall cost of ownership during its entire useful life.

Thanks to its “Snap-In” functionality, the new Focus is also made to function well with the FARO Freestyle 2 Handheld Scanner. When scanning complicated environments/structures, equipment, or confined areas, reduce the time needed for several scanner locations.

Gather Production Data Accurate data enables trend analysis and reporting.