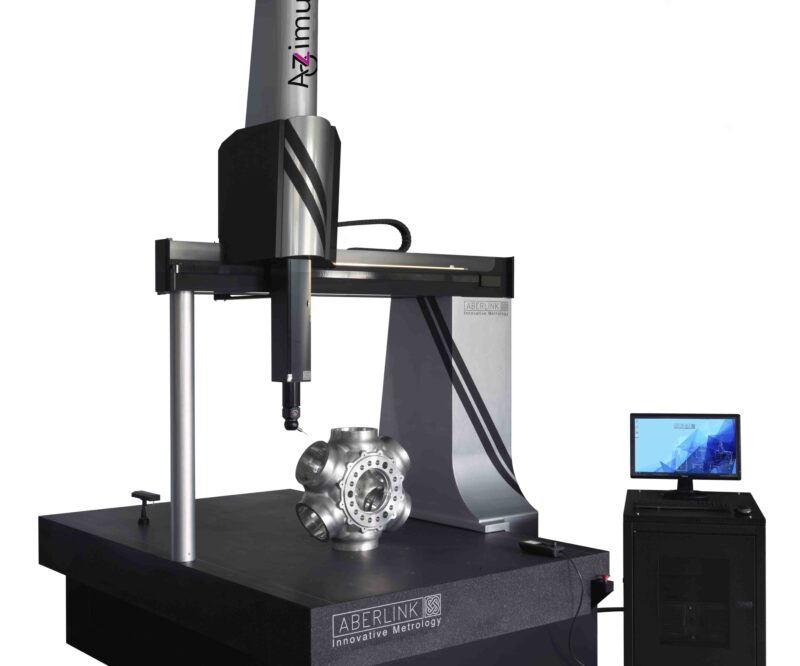

It is not enough to just scale up the design of smaller versions as CMMs get bigger. While the structure’s stiffness is important, weight must also be kept to a minimum. In addition to being the largest CMM product offered by Aberlink, the Azimuth CMM is the result of more than 20 years of excellence and experience in the design and production of cutting-edge metrology equipment that uses cutting-edge materials technology.

Developed for use in Formula One and the aerospace industry, aluminium honeycomb sheets are incorporated into the ground-breaking Azimuth bridge. This offers an amazing stiffness to weight ratio, which gives the Azimuth an advantage in terms of performance and speed.

The innovative mechanism on the Y axis means that there is no performance deterioration across the full range of machine sizes available up to 3m, and the drive systems created for the Azimuth offer simplicity and durability. Aberlink has demonstrated inventive thinking in another domain: measuring heavy components using a large machine. We provide a specially made load plate to rest on the granite base instead of just deepening the granite table, which significantly increases the machine’s weight and expense.This plate has the capacity to support a six-ton force, which will be transmitted via the machine bench’s foot and directly to the floor with no loss of metrological performance.

|

Azimuth CMM |

Maximum Performance |

SPECIFICATION

| Axis Travel (mm) | X 1200 Y 2000, 3000 Z 1000 |

| Overall Size (mm) | X 1940 Y 3000, 4000 Z 3595 |

| Motion | CNC |

| Structure | Bridge |

| Suitable for | Inspection Room |

| Drive Type | Belt |

| *Volumetric Accuracy | TP20 (2.9 + L/250)µm TP200 (2.8 + L/250)µm SP25M (2.6 + L/250)µm |

| Scale Resolution | 0.1µm |

| **Optimum Temp Range | 18 – 22°C |

| Operational Temp Range | 5 – 45°C |

| Table Construction | Solid Granite |

| Table Load Capacity | 1500kg |

| Max. Velocity Vector | 600mm/sec |

| Max. Acceleration Vector | 600mm/sec² |

| Air Required | Yes |

| Air Consumption | 65 l/min (1.8 cfm) |

| Required Air Pressure | 5 bar (72 psi) |

| Aberlink Camera Support | Yes |

*Maximum Permissible Error MPEE within the thermal limits defined for optimum temperature range. **Installation environmental thermal limits: Rate of change <1°C/hr and <2°C/24hr. Temperature gradient <1°C/m

- *Minimum measuring range specified because the usable volume isn’t cubic.**Maximum Permissible Error MPEE, according to an adapted ISO10360-2 2009 test to suit the Fulcrum, within the thermal limits defined for optimal temperature range.***The machine should not be positioned where it will be subjected to rapid changes in temperature. Max rate of ambient temperature change should not be more than 1°C/hour.