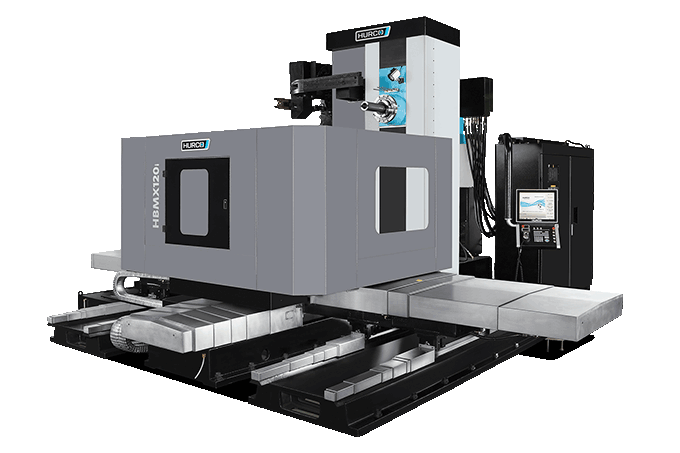

Discover the exceptional Horizontal Boring Mill! Unlike other mills in its class, the HBMX120i is robust, offering a larger work envelope and hardened box ways. With a two-speed geared head spindle, it’s designed to deliver superior performance and precision.

HBMX120i

SPECIFICATION

Travels & CapacityX, Y, Z, W Axis Travel |

118.1 x 70.1 x 66.9 x 19.7 in (3,000 x 1,780 x 1,699 x 500 mm) |

| Table Working Surface | 56.7 x 63 (1,440 x 1,600 mm) |

| Max. Weight on Table | 13,889 lbs. (6,299 kg) |

| Table T-Slots | 9 x .9 in on 6.3 in centers (228 x 22 mm on 160 mm centers) |

| Spindle Nose to Table Center | 5.1 to 89.8 in (130 to 2,280 mm) |

| Floor to Table Surface | 42.1 in (1,070 mm) |

SpindleSpindle Speed |

8-454 (low), 8-2,500 (high) rpm (8-454 rpm (low), 8-2,500 rpm (high)) |

| Spindle Motor Power (10 min.) | 40.2 HP (29.9 kW) |

| Spindle Motor Torque (1 min.) | 1,106 ft lbs. (low) ,303.9 (high) ft lbs (1,500 (low), 412 Nm (high)) |

Feedrates / MotionRapid Traverse Rate X/Y/Z Axes (ipm) |

393.7 in/min (10 m/min) |

| Rapid Traverse Rate W-Axis | 157.5 in/min (4.0 m/min) |

| Max Programmable Feedrate | 393.7 in/min (10 m/min) |

| Least Command Increment | .0001 in (0.002mm) |

| Positioning Accuracy (10 pass VDI 3441 Method) | .001 in (0.025mm) |

| Repeatability (10 pass VDI 3441 Method) | .0006 in (0.015mm) |

| Positioning Accuracy B | +/- 9 arc seconds (+/- 18 arc seconds) |

| Repeatability B | +/- 6 arc seconds (+/- 12 arc seconds) |

Tool ChangerSpindle Taper |

CAT 50 |

| Number Of Tools | 60 (90 opt) |

| Tool Changer Type | Electronic |

| Maximum Tool Weight | 55.1 lbs. (25 kg) |

| Maximum Tool Diameter | 4.7 in (120 mm) |

| Maximum Tool Length | 15.7 in (400 mm) |

GeneralCoolant Capacity |

132.1 gallons (500 liters) |

Optimum machine performance is reliant upon installation conditions at the facility, such as power supply, air supply, and ambient air conditions. Information may change without notice.

- *Minimum measuring range specified because the usable volume isn’t cubic.**Maximum Permissible Error MPEE, according to an adapted ISO10360-2 2009 test to suit the Fulcrum, within the thermal limits defined for optimal temperature range.***The machine should not be positioned where it will be subjected to rapid changes in temperature. Max rate of ambient temperature change should not be more than 1°C/hour.