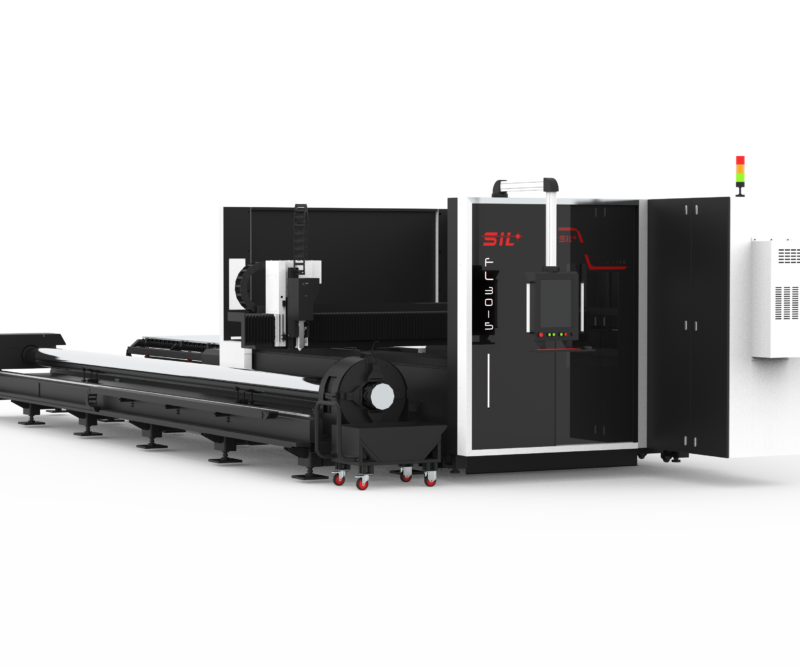

High-tech flexibility in 2D and rotary cutting is best demonstrated by the Fiber Laser Metal Sheet-Pipe Cutting Machine. Its smooth integration of beam-modulation technology enables it to automatically adapt power and speed to the thickness of the material, making transitions between cutting flat sheets and tubes or pipes more efficient. This unique method offers exceptional adaptability in processing round, square, rectangle, C-channel, and angle iron in a matter of minutes. The machine’s continuous variable beam capabilities eliminates the need to switch lenses and guarantees constant cutting quality across a range of material thicknesses. The laser beam diameter and cut width increase in direct proportion to the thickness of the material, making it easier to remove finished pieces and guaranteeing quick output.

Specifications

| Laser Power | KW | 01-Apr |

| Laser Model | IPG/Raycus | |

| Work Size | mm | 3000×1500 |

| Positioning Accuracy | mm/m | ≤±0.05 |

| Rotary Size (Combo) | mm | 165/220 Ø |

| Max Idle Speed | m/mm | 60 |

| Repositioning Accuracy | mm | ≤±0.03 |

| Power | V/Hz | 380/50 |

| Cutting Acceleration | G | 0.5 |

| Weight | Kg | 8000 |

| Controller | Cypcut | |

| X Axis | mm | 1520 |

| Y Axis | mm | 3050 |

| Z Axis | mm | 300 |

SAMPLES