5-AXIS CNC MACHINE LINEUP

Enhance Your Work

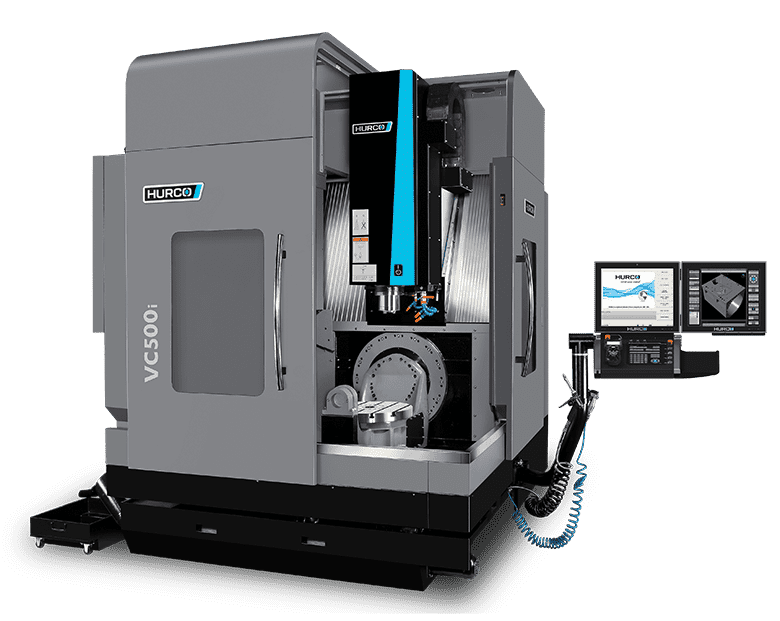

U-Series5-Axis CNC Machines

One important advantage of 5-axis trunnion table machining centers is their efficient design. An integrated trunnion table rather than merely mounting a trunnion table on a 3-axis milling machine and calling it a 5-axis machine. In comparison to the add-on table configuration, the integrated trunnion table design offers better clearance in Z.

Read More

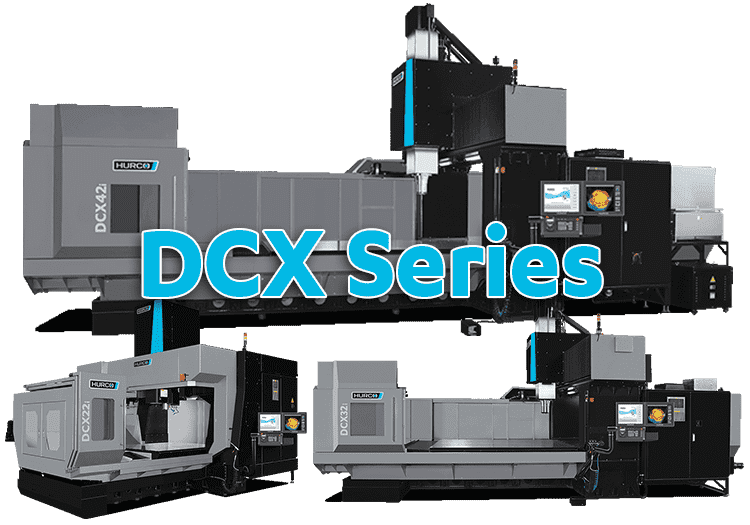

DCX Series

5-Axis CNC Machines

Customers that wanted larger machines for aerospace and energy parts and already knew Hurco's worth led to the creation of the DCX Series of Double Column CNC machining centers. With the robust Hurco control, our 2-, 3-, and 4-meter VMCs are the largest machine tools on the market.